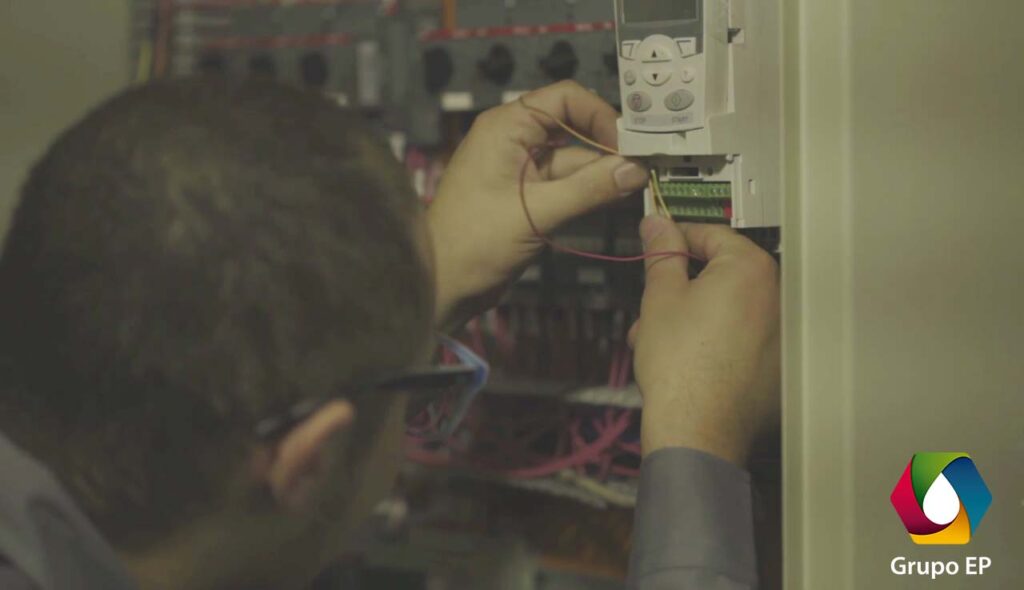

WTP and WWTP automation is the use of technologies and systems to automate processes and tasks in thermal power plants (WTP) and water treatment plants (WWTP). Automation can include process control, real-time monitoring, data analysis and equipment management to increase efficiency, reduce errors and ensure safety.

EP is a water and effluent treatment company that plays a fundamental role in preserving the environment and in finding solutions for managing your business. It has been working with great dedication and multiplying results for over 50 years.

Water or sewage is collected in collection networks and transported to the plant.

Removes solid particles through processes such as flocculation, sedimentation and filtration.

Use of chemical reagents to remove dissolved substances from water or sewage.

Use of microorganisms to degrade organic matter in water or sewage.

Use of processes such as chlorination to kill microorganisms present in treated water.

Treated water is stored and distributed for public consumption or treated sewage is disposed of safely.

Automation makes it possible to optimize and continuously monitor the treatment process, improving efficiency and reducing the waste of resources.

Automation provides accurate and constant data to adjust and optimize treatment processes.

Automation enables continuous monitoring and a rapid response in the event of faults or security problems.

Automation can reduce operating costs over time, improving efficiency and reducing the need for manpower.

Automation makes it possible to control and guarantee the quality of treated water or treated sewage.

Automation makes it possible to keep up with and meet constantly evolving regulatory requirements.

ETA and ETE automation applications include: