Water scarcity is an imminent problem in many Brazilian regions, making water reuse a great ally in the sustainability of many companies’ businesses. Reverse Osmosis (RO) systems, also known as Reverse Osmosis, are capable of purifying water by removing dissolved salts from semi-permeable membranes, producing water with a low salinity of around 75% compared to the input water.

The challenge in operating RO systems lies in the ability to produce low-salinity water with as little intervention as possible with periodic chemical cleaning stops when their flow rate decreases, the pressure differential increases, and/or the salt rejection decreases. Typically, interventions occur due to the characteristic of the RO system’s own feed water, and may be associated with a need for pretreatment or inefficient pretreatment. In the field, some analyses must be performed to monitor the equipment, among them the SDI.

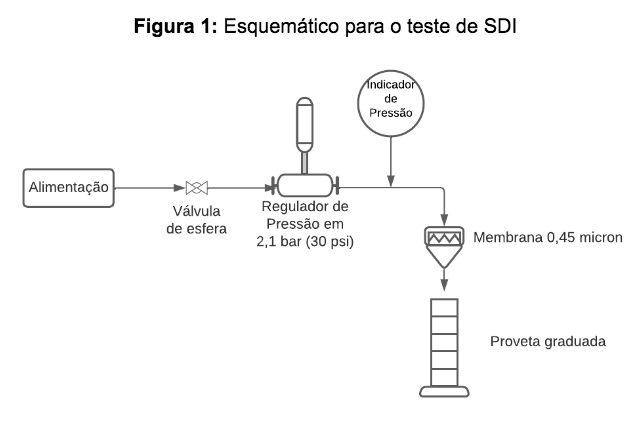

The SDI (Silt Density Index) is a recommended test to be carried out directly in the field on the feed water, based on the variation in fouling of a microfiltration membrane at a constant pressure during the time required to filter the volume defined by the standardized analytical protocol. Below is the schematic of figure 1:

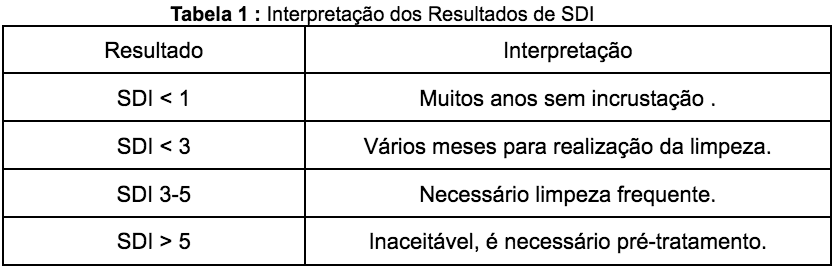

After stabilizing the pressure at 2.1 bar (30 psi), the test is started by collecting volumes of 500 mL at different times, initial and final, and applying the formula below the SDI, the result is obtained and interpreted according to the table below.

The following formula is used to calculate the SDI:

SDI =100*(1-Ti/Tf)/T

In which:

Ti = Time needed to reach 500 ml.

Tf = Time needed to reach 500 ml after filtration of 15 minutes.

T = Total test time.

The result obtained is interpreted in this table 1, favoring immediate action, taking into account the need for continuous improvement of the process with the goal of high productivity.