Have you ever wondered what role a treatment plant engineering company plays in the daily lives of industries and sanitation companies?

At EP, we transform projects into complete solutions that guarantee water quality and the proper treatment of effluents, always in compliance with environmental standards. We work from initial diagnosis to assisted operation, delivering safety, sustainability and efficiency.

What is a treatment plant engineering company?

An engineering company specializing in treatment plants plays a crucial role in water management and environmental protection. Its responsibilities cover the complete development cycle of Water Treatment Plants (WTPs) e Sewage Treatment Plants (STPs)from initial design to delivery and operation.

The work of these companies is fundamental to guaranteeing operational reliability, access to quality reuse water, drinking water and basic sanitation, contributing directly to public health, the preservation of ecosystems and meeting the goals of a wide range of companies.

Main services offered by EP

How treatment plants work

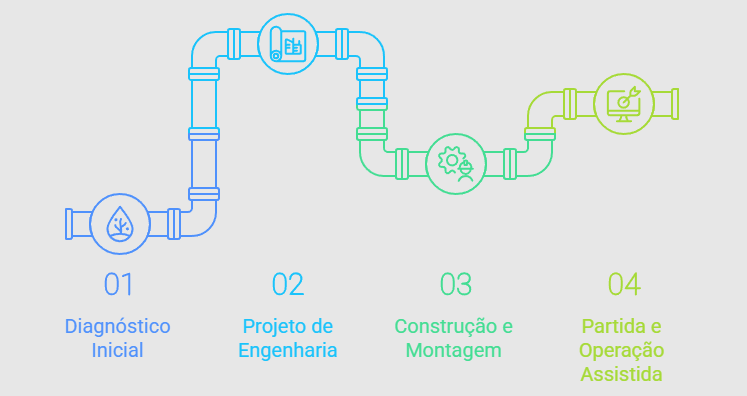

We follow a rigorous and comprehensive process to guarantee effective and sustainable solutions for the success of your project:

Initial Diagnosis – Detailed analysis of water or effluent quality:

This fundamental phase begins with an in-depth analysis of your specific needs. Our team of experts collects water or effluent samples and subjects them to a series of tests for characterization in our accredited laboratory.- Engineering Project – Strategic definition of physical, chemical and biological processes:

After the diagnosis, our engineers develop a customized engineering project that integrates the most advanced treatment technologies. This stage involves the careful selection and sizing of physical, chemical and biological processes, resulting in a project that not only meets disposal or reuse standards, but is also economically viable and environmentally responsible. - Construction and assembly – Integrated execution of civil, electromechanical and automation work:

Once the project has been approved, we begin the construction and electromechanical assembly phase, transforming the plan into a functional treatment plant. Safety at work and the quality of execution are continuously monitored.

Automation is a key component, with the installation of electrical panels, PLC (Programmable Logic Controller) control systems, sensors and actuators that allow the plant to be operated and monitored efficiently, minimizing the need for manual intervention. - Start-up and Assisted Operation – Continuous technical support until the plant is stable:

The final stage is the start-up of the treatment plant, where we put the entire system into operation, test the components, adjust operating parameters and check the functionality of each subsystem.

We offer a period of assisted operation, during which we provide technical support and train the client’s operating team, ensuring that they understand how the plant works, the procedures and the best operating practices.

Our commitment is to ensure that the station delivers the expected results in the long term.

The selection of an engineering company specializing in treatment plants represents a strategic investment in reliability, sustainability and the achievement of results.

At EP, each project is carried out with technical rigor and a focus on environmental performance, helping our clients to comply with current regulations and improve their operational efficiency.

Author: Rafael Pacheco