Find out what industries need to review now to mitigate risks, reduce costs and ensure environmental compliance all year round.

The start of a new year is the ideal time for industries to review their environmental and operational processes.

When it comes to wastewater treatment plants, planning is synonymous with efficiency, economy and regulatory safety.

With this in mind, in this article we’ve put together an essential checklist for an efficient WWTP in 2026, helping your company to anticipate problems, optimize resources and keep the operation in compliance with environmental legislation.

1. strategic preventive maintenance

Review the WWTP’s preventive maintenance plan, ensuring operational predictability and avoiding unscheduled downtime throughout the period.

Rather than replacing components on schedule, strategic preventive maintenance must take into account the actual performance of the plant, the operating history and the risks associated with each treatment stage.

In this planning, it is essential to assess the useful life, efficiency and need for modernization of critical components, such as:

- Filter media such as sand e activated carbon

- Filter media such as sand e activated carbon

Defining the correct time for replacement must take into account technical indicators such as pressure drop, removal efficiency, frequency of corrective interventions and changes in the effluent load.

A well-structured preventive maintenance plan reduces emergency costs, increases treatment efficiency and ensures greater operational stability of the WWTP throughout the year.

2. Carry out a legal compliance study

Environmental legislation is constantly being updated. One legal compliance study is essential to check that your industry is in line with current standards and new regulatory requirements, such as SS Resolution 195, which establishes stricter criteria for controlling the quality of water intended for human consumption, requiring analyses carried out by laboratories accredited in accordance with ISO 17.025.

This diagnosis reduces the risk of fines, penalties and impacts on the company’s reputation.

Did you know that in Brazil fines for environmental damage can reach up to 50 million reais?

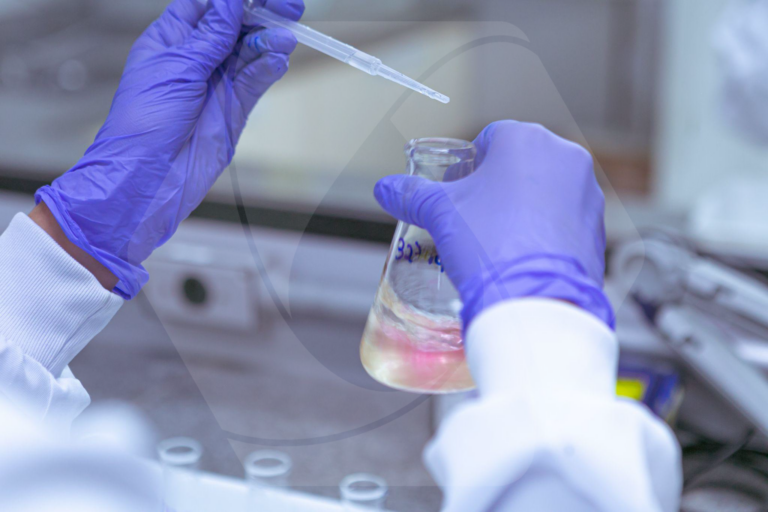

3. Rely on an accredited environmental analysis laboratory

Another critical point is to review who carries out the laboratory analyses of your WWTP.

Prioritize an environmental analysis laboratory accredited to ISO 17025guaranteeing:

- Reliability of results

- Traceability of information

- Technical security in audits and inspections

4. Review the efficiency of effluent treatment

The key question is: “Does my WWTP have the best treatability route?”

To answer this, it is essential to identify whether there are bottlenecks in the biological, physical-chemical or tertiary treatment processes.

An efficient treatment route is sustainable for the environment and the business, avoiding unnecessary expenditure on chemicals, energy and excessive maintenance.

Grupo EP has an exclusive department for solving complex problems with water treatment, effluents and reuse. The expertise of PDI (Research, Development and Innovation) is essential for assessing the biodegradability of the effluent, testing different treatment routes and validating, on a bench scale, the most efficient solution for each industrial reality.

5. Invest in modernization, data management and monitoring of the WWTP

In 2026, data and advanced digital technologies such as IoT, Artificial Intelligence and Big Data will cease to be a differentiator and will become a determining factor for operational efficiency, and industrial effluent treatment is no different.

Modernize the ETE by retrofitting systems and upgrading technologyThis means more organization, predictability and far fewer “headaches” in the operational routine. By adopting remote monitoring and intelligent data management solutions, your industry can operate with more control and predictability. A practical example is STEP, a solution developed to integrate online monitoring, data traceability and technical decision-making support.

With STEPyou can guarantee:

- Traceability of auditable data for ESG reports and environmental inspections

- Clear performance indicators for the treatment plant

- Online and real-time monitoring of the WWTP

- Decision-making based on data, not assumptions

- Less dependence on reactive actions, reducing operational risks

In addition, outsourcing the online monitoring of the WWTP allows the industry to have expert technical insight and continuous control of the operation, with less internal effort and greater efficiency throughout the year.

6. Evaluate the station’s operating costs

A detailed analysis of operating costs makes it possible to identify hidden waste that compromises the efficiency of the WWTP. Evaluate in particular:

- Consumption of chemical products

- Sludge generation and disposal

- Energy consumption

- Corrective versus preventive maintenance hours

Small operational adjustments can generate big savings over the course of the year. You can count on a company that has been specializing in industrial effluent treatment for over 50 years.

7. Evaluate water reuse opportunities

Water reuse is no longer a trend but a strategy. Check it out:

- Where treated water can be reused in the industrial process

- The potential for water and financial savings

- If the current system allows this adaptation

A consultancy specializing in water reuse helps identify real, safe and viable opportunities. Talk to Grupo EP’s experts and find out how to implement water reuse solutions according to your industry’s operational reality.

Count on a specialized technical partner

This whole checklist can seem complex – and indeed it is when the industry tries to manage everything internally. The good news is that you don’t have to do it alone.

By outsourcing the management, monitoring and operation of the WWTP, your company gains predictability, regulatory security and operational efficiency, while the in-house team can focus on core business. This is exactly where Grupo EP acts as a technical partner.

With more than 50 years’ experience in industrial effluent treatment, EP Group offers an integrated approach ranging from engineering, laboratory analysis and treatability studies to operation, online monitoring, water reuse and continuous improvement of the plant based on data, clear indicators and legal compliance.