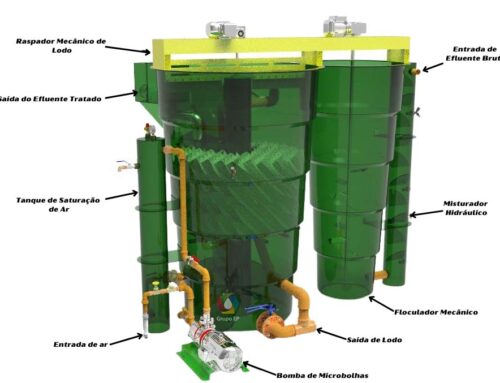

The Dissolved Air Flotation System is a water treatment technique that uses air bubbles to remove suspended solids and liquids from the water. Air bubbles are injected into the dirty water, bringing suspended materials to the surface where they can be removed. This technique is often used to treat sewage, industrial process water and public supply water.

Operating Process

The operating process of a dissolved air flotation system generally consists of a few basic steps:

- Pretreatment: Dirty water is pretreated to remove coarse materials such as sand and mud and to control acidity and alkalinity.

- Air injection: Air is injected into the dirty water through injection nozzles or diffusers, forming dissolved air bubbles.

- Flotation: Air bubbles cling to suspended materials in the water, bringing them to the surface. These materials form a floating layer known as foam.

- Foam Removal: Foam is removed from the water surface with mechanical skimmers or similar devices.

- Post-treatment: Treated water is passed through a post-treatment process, such as filtration or disinfection, before being released into the environment or reused.

- Air recycling: The air used in flotation is recycled and reused in the system.

Floating materials removed from the dissolved air flotation system are generally treated as waste and disposed of properly.

A dissolved air flotation system offers several benefits, including:

- Efficient removal of suspended materials: Dissolved air flotation is highly efficient at removing suspended materials such as oils, grease, sand and mud from water.

- Flexibility: Dissolved air flotation is flexible and can be used in a variety of applications, including wastewater treatment, industrial process water treatment, and public supply water treatment.

- Low energy consumption: Dissolved air flotation generally requires low energy consumption, making it a cost-effective water treatment option.

- Low cost: Dissolved air flotation is generally less expensive than other water treatment techniques such as membrane filtration or chemical precipitation.

- Air recycling: The air used in flotation is recycled and reused, which contributes to the energy efficiency of the system.

- Low environmental impact: The dissolved air flotation system has a low environmental impact, as it generally does not use chemicals to treat water.

Applications

A dissolved air flotation system can be used in a variety of applications, including:

- Sewage Water Treatment: Dissolved air flotation is widely used to treat sewage water by removing suspended solid and liquid materials such as oils, greases and sludge particles.

- Industrial process water treatment: Dissolved air flotation is used to treat water used in industries such as metallurgy, pulp and paper, food and beverage, and mining, among others.

- Treatment of public supply water: Dissolved air flotation is used to treat public supply water, removing suspended solids and liquids and improving water quality.

- Fish farming water treatment: Dissolved air flotation is used to treat water used in fish farming, removing suspended particles and improving water quality.

- Oil and Gas Wastewater Treatment: Dissolved air flotation is used to treat wastewater from oil and gas operations, removing oils and grease.

- Resource recovery: Dissolved air flotation can be used to recover valuable resources, such as metals, from solutions or suspensions.