Activated sludge is a wastewater treatment process that uses bacteria to remove organic and inorganic pollutants. It consists of three steps: aeration, clarification and anaerobic digestion. In the aeration step, bacteria are added to the wastewater and oxygenated so they can grow and reproduce. In the clarification step, sludge is removed from the treated water. In the anaerobic digestion step, the sludge is kept in a closed tank without oxygen, where bacteria break down the sludge into carbon dioxide and water. This process increases treatment efficiency and generates biogas as a by-product.

working process

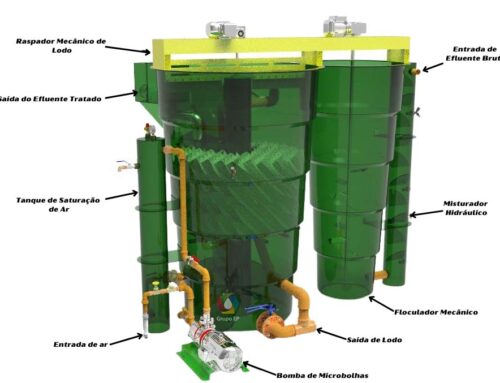

The operating process of an activated sludge system is generally divided into three main stages: aeration, clarification and anaerobic digestion.

- Aeration: Wastewater is pumped into an aeration tank where it is mixed with bacteria and oxygenated. The bacteria use the organic pollutants present in the water as a food source and grow and reproduce. This causes pollutants to biodegrade and be removed from the water.

- Clarification: The treated water is then pumped into a clarification tank, where the sludge is separated from the treated water. Sludge is regularly removed and forwarded to the next step.

- Anaerobic digestion: The removed sludge is then conveyed to an anaerobic digestion tank, where it is kept in oxygen-free conditions. Under these conditions, the bacteria present in the sludge continue to decompose the remaining organic pollutants, generating biogas (mainly methane) as a by-product.

At the end of the process, the treated water is released into water bodies, and the treated sludge can be used as organic fertilizer.

Benefits

An activated sludge system has several benefits, including:

- Treatment efficiency: An active sludge system is capable of removing a wide variety of organic and inorganic pollutants from wastewater, making the treated water suitable for reuse or disposal into water bodies.

- Biogas generation: The anaerobic digestion of sludge generates biogas as a by-product, generally composed mainly of methane. This biogas can be captured and used as a source of clean energy.

- Reduction in waste volume: Treated sludge can be used as organic fertilizer, reducing the need for space for storing waste and the environmental impact.

- Low cost: Active sludge systems are generally more economical than other wastewater treatment systems, especially if the generated biogas is used as an energy source.

- Easy to Operate and Maintain: The active sludge system is relatively easy to operate and maintain, and can be scaled to meet varying flow requirements.

Applications

Activated sludge systems are widely used across multiple industries to treat wastewater, including:

- Industry: active sludge systems are commonly used to treat wastewater from the food, beverage, pulp and paper, chemical, pharmaceutical, and other industries.

- Municipalities: Active sludge systems are often used in municipal wastewater treatment plants to treat domestic and industrial wastewater.

- Agriculture: Active sludge systems can be used to treat wastewater from animal feed facilities and fish farms.

- Isolated communities: Active sludge systems can be used in isolated communities, such as islands and remote villages, to treat domestic and industrial wastewater.

- Water Treatment Facilities: Active sludge systems can also be used in water treatment facilities to remove organic and inorganic pollutants from raw water before it is distributed for human consumption.