The effluents generated in an automotive plant, for example in the automobile industry, are always a cause for concern because they contain substances such as oils and greases, surfactants, and metals such as zinc, boron, and others.

In this context, another pressure that the industries have been suffering is the increase in the tariffs for water supply and sewage collection, which were readjusted last year by 12.82%, reaching more than R$ 50.00 per m³.

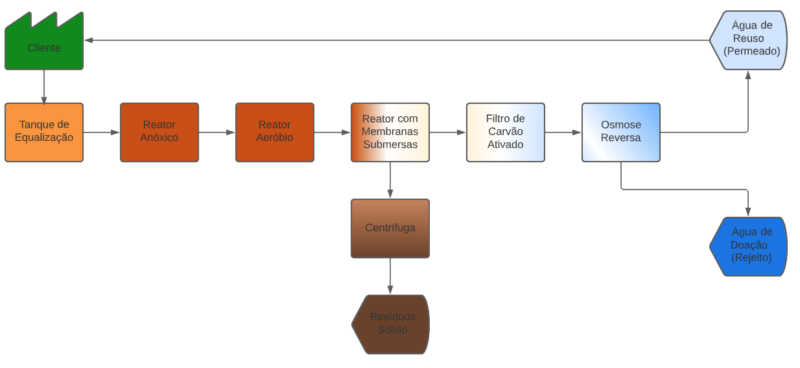

EP Engenharia do Processo, through its expertise, offers our clients reuse solutions using state-of-the-art technologies, such as membrane bioreactor systems (MBR) and reverse osmosis desalination. Below is a process flowchart applied for this customer.

As a result, the first impact was financial, where of the 100% of the effluents generated in the factory, about 87% return to the industry as reuse water and the remaining 13% are donated for cleaning and wetting roads. Thus, the expectation is that we will save, within 12 months, more than R$4,800,000.00, returning the investment in less than 2 years.

Check out the other various processes and systems that EP Engenharia performs in our products and services pages, learn more about other treatment systems, and other EP Group highlights at

our blog!